Mono-material

BOPE & BOPP Films for Recyclable Flexible Packaging

Why Switch to Mono-Material Films?

Traditional multilayer films (like PET/PE or PA/PE) are difficult to recycle. At BIOXPACK, we help brands and converters transition to fully recyclable packaging structures by offering BOPE and BOPP mono-material films.

Circularity

Single polymer family =

easier recycling

Downgauging

Reduce plastic without losing performance

High-speed compatibility

Flow-pack, FFS, cartoning lines

Regulatory alignment

Ready for EU 2030 & EPR schemes

BOPE & BOPP Solutions

BOPE Films — 3NHD Range

Our BOPE (Biaxially Oriented Polyethylene) 3NHD films are ideal for recyclable, laminated PE structures.

Key advantages:

- Excellent flatness and stiffness

- Printable, metallizable, laminable

- High optical clarity

- Corona-treated or untreated versions

Applications: bakery, snacks, pet food, pouches, doypack

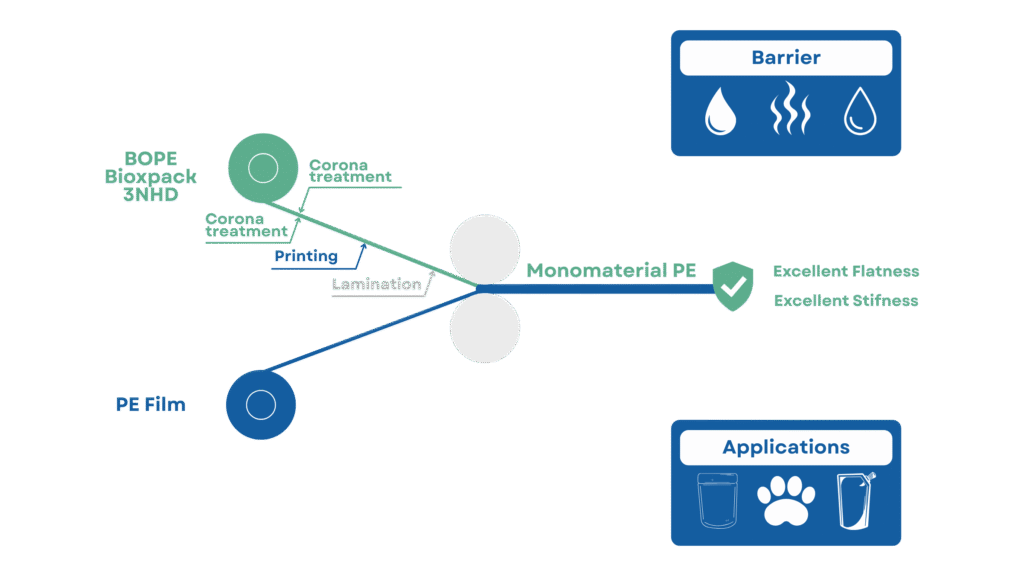

How the Monomaterial PE Structure Works

BIOXPACK’s 3NHD film integrates perfectly into laminated PE monomaterial structures. The example below shows how it replaces PET/PE:

3NHD-Based Recyclable Laminate

Ideal for: food pouches, sachets, pet food bags, doypacks

BOPP Films — ER-PP Range

Our ER-PP range is a mono-material BOPP solution engineered for food, cosmetic and pharmaceutical packaging that requires barrier protection, downgauging, and flow-pack compatibility.

Key features:

- High gloss and optical appeal

- Gas and moisture barrier

- Alcohol resistance (optional)

- Grades with low/high COF

- Printable, metallizable, sealable

Applications: biscuits, tea bags, wipes, single-dose formats

Benefits

100% recyclable mono-material structures (BOPE or BOPP)

Reduced grammage for lower plastic consumption

Designed for high-speed lines — flow-pack, cartoning, VFFS

Printable, sealable, and laminable without structural complexity

Compliant with EU regulations and circular economy goals